- Equipment

- Rollforming lines

- Lines for tile production

- Lines for corrugated profile production (mono)

- Lines for corrugated profile production (universal)

- Equipment for production of the elements of rainwater system

- Lines for roof elements production

- Lines for siding and special profile production

- The Equipment for manufacture of panels of prefabricated buildIngs

- Rollforming tool

- Flying scissors

- Slitting and cutting-to-length lines

- Cross-wedge rolling and Helical-rolling line

- Induction heaters

- Support equipment

- Main/

- Cross-wedge rolling lines WRL TS series

Cross-wedge rolling lines WRL TS series

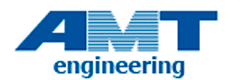

AMTengineering is a manufacturer of cross-wedge rolling lines and cross-wedge rolling machine of the WRL and WRL TS series with a patented design. The equipment is protected by over 20 patents and inventions. This is a better type of cross-wedge rolling line than forging rolls. Due to the use of a flat forming tool and a more rigid frame design, the positioning of the rolled workpiece does not require calibration, and the dimensional accuracy in diameter is maintained within 0.1 mm and 0.01 mm for special designs (no elasticity and bending after after rolling).

AMTengineering mills, in contrast to mills of other manufacturers, have a rigid closed structure, designed, depending on the size, for a thrust force from 100 to 1000 tons. programmable flow rate (option) or in manual mode by the operator during routine maintenance. Rolling guides reduce the rolling force by 40% and the drive power of the hydraulic station by 50%, which allows increasing the travel speed of the crosshead (tool drive) up to 180 m / min (in other manufacturers' mills up to 30 m / min). From the operating experience during the operation of the mill in three shifts, the guides without replacement and grinding worked for 12 years. Due to the high rolling speed, the contact time of the hot workpiece with the tool is significantly reduced and, accordingly, the heating of the tool decreases and, as a result, its durability increases (at a high deformation rate, the metal fills the mold much better).

Cross-wedge rolling line WRL TS series is a further development of WRL series. It is designed to produce parts like solids of revolution by the method of warm and hot rolling. Line WRL TS series has two movable die that allows to use wedge die up to 3,5 m in length, and produce preforms up to 300 mm in diameter. The increased length of the tool allows for single, double, triple rolling of parts.

|

Model |

WRL 2510 TS |

WRL 6316 TS |

WRL 9018 TS |

WRL 8020 TS |

WRL 10025 TS |

WRL 13030 TS |

WRL 20035 TS |

WRL 30060 TS |

|

Diameter of rolled blanks, mm |

25 |

65 |

90 |

80 |

110 |

130 |

200 |

300 |

|

Length of rolled blanks, mm |

250 |

350 |

500 |

500 |

600 |

600 |

1200 |

2800 |

|

Productivity, pcs / hour |

720-900 |

450-600 |

360-500 |

360-450 |

120-240 |

90-180 |

60-180 |

60-120 |

|

Tool length, mm |

1000 |

1600 |

1800 |

2000 |

2500 |

3000 |

3500 |

6300 |

Obtaining forgings (parts) such as bodies of revolution from various grades of steels and alloys (titanium, non-ferrous, difficult to form) by cold, warm and hot rolling.

Advantages of the WRL and WRL TS series cross-wedge rolling line:

- metal utilization factor 0.8-0.98

- slider travel speed up to 180 m / min

- tool change time 20-30 minutes (with an automatic gripping system up to 5 minutes)

- single, double, triple rolling of parts possible

- tool life is 20 times higher compared to GCM

- no expensive equipment is required for the production and repair of flat tools

- most effective when rolling a large range of high-precision parts of complex configuration.

- automatic tuning system, adjusting all parameters in the process of line operation.

- strengthening of the structure of the part and the absence of ellipticity

- rolling of asymmetrical parts

- increase in the period of overhaul intervals of dies

- work in conjunction with induction heaters TFC with continuous control of the input and output temperatures of the workpiece allows to reduce energy consumption and improve the quality of stampings by reducing scale formation.

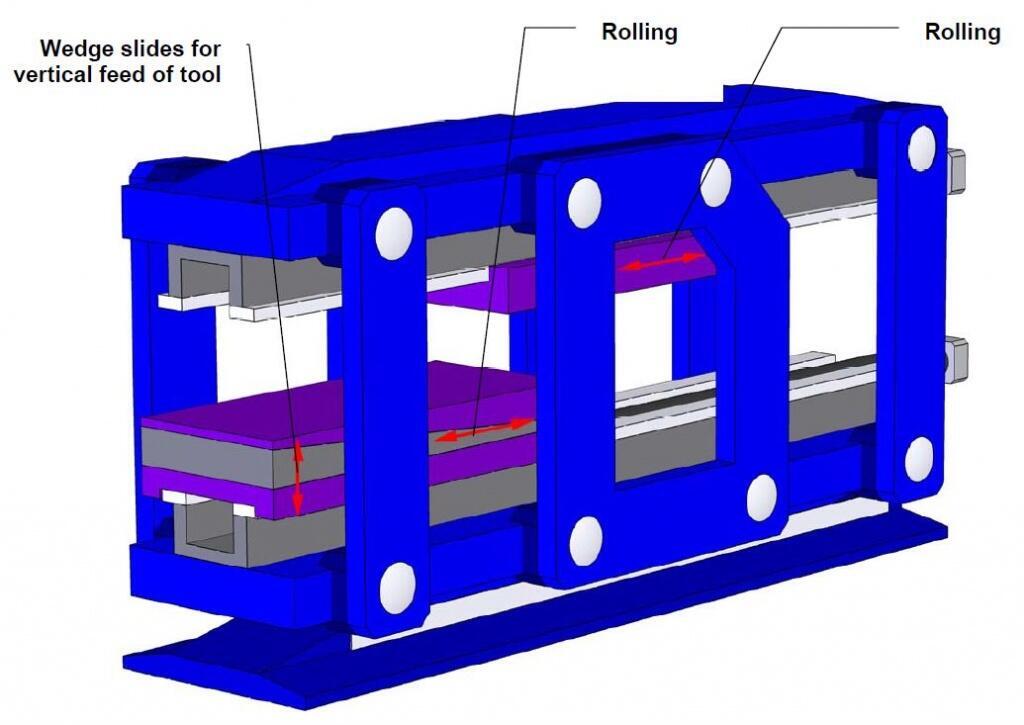

Efficient cooling or heating system for rolling tools

At present we have designed and manufactured the following models of the lines series WRL TS: WRL9018TS, WRL9025TS, WRL10025TS.

The model name is determined by the maximum diameter of a billet and by the length of a rolling tool.

For example, a line WRL9025TS is designed for rolling of billets with maximum diameter of 90 mm and has a length of rolling tool 2500 mm.

Single-piece rolling output of the lines WRL TS series can reach 900 parts/hour (depending on RF current heating power). The output of pair rolling is doubled.

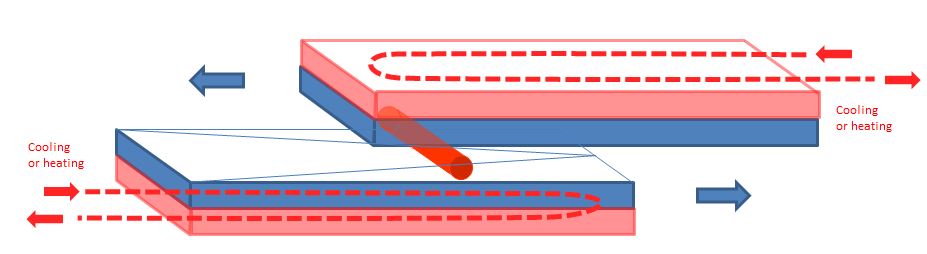

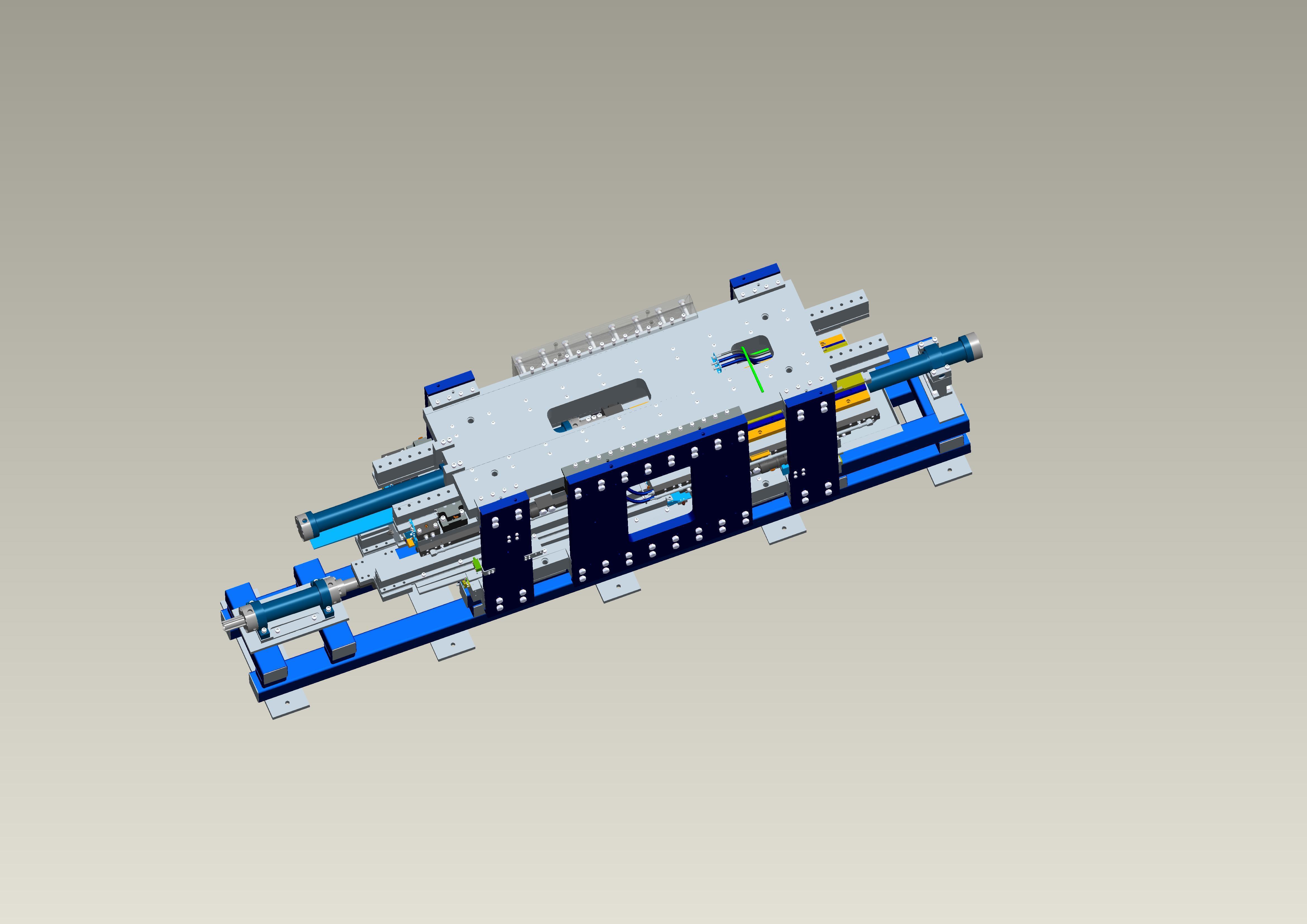

3D model of the cross-wedge rolling line

Cross-wedge rolling line WRL9018TS - production of shafts for gear hydraulic pumps

Cross-wedge rolling line WRL9025TS - production of forgings for suspension parts of trucks

Cross-wedge rolling line WRL10025TS - production of billets for gearboxes and final drives of commercial and freight vehicles.

Cross-wedge rolling lines are best suited for forging and pressing industries aimed at reducing metal waste, improving the technological process in conditions of mass production of parts. According to the experience of our customers, the cross-wedge rolling lines with flat tools of the WRL and WRL TS series allow solving the tasks set for the equipment and closing questions for a long time. Rolling mills produced by our company AMTengineering, supplied to customers, in the mode of 2-3 shift operation due to the incorporated technical solutions have been operated for decades for Mexica, USA and countries in Eastern Europe.

Download catalog - Cross-wedge rolling lines WRL TS series