- Equipment

- Rollforming lines

- Lines for tile production

- Lines for corrugated profile production (mono)

- Lines for corrugated profile production (universal)

- Equipment for production of the elements of rainwater system

- Lines for roof elements production

- Lines for siding and special profile production

- The Equipment for manufacture of panels of prefabricated buildIngs

- Rollforming tool

- Flying scissors

- Slitting and cutting-to-length lines

- Cross-wedge rolling and Helical-rolling line

- Induction heaters

- Support equipment

- Main/

- Helical rolling lines and mills HRL series

Helical rolling lines and mills HRL series

Cross-helical rolling (the principle of hot radial shear screw rolling (RSVP)) is successfully used for the production of KAV screw roof bolts (ground support), tie screws for formwork, railway rough axles, grinding balls (rolled steel grinding balls), and so on. the same elongation of heated workpieces from a larger diameter to a smaller one (programmable stepping is possible). Cross-helical rolling lines (helical rolling mill) of the HRL series produced by the Engineering Center AMTengineering have a full range of automation and flexibility of integration into the customer's technological process.| Model |

HRL 3020 |

HRL 8010 |

HRL 10035 |

|

Diameter of rolled blank up to, mm |

30 |

80 |

100 |

|

Length of rolled blank up to, mm |

2000 |

1000 |

3500 |

|

Productivity, pcs / hour |

60-360 |

120-360 |

60-100 |

|

Diameter of forming rolls, mm |

120 |

150 | 200 |

Obtaining forgings (parts) such as bodies of revolution from various grades of steels and alloys by warm and hot rolling.

The complex of equipment for cross-helical rolling is used to automate the manufacture of a large range of axisymmetric parts of different standard sizes and configurations on one tool (one tool - different standard sizes of parts).

Screw rolling lines are successfully used for the production of:

- Rock bolting

- Formwork clamping screw

- Rough rail axle

- Shafts of transmissions

- Suspension parts

- Grinding balls 20-160 mm

Example: Line HRL80-10

- Work with workpieces with a diameter of 30 - 80 mm;

- Limitation of receiving and feeding tables for working with workpieces with a length of 100 mm to 1000 mm

- The change of three forming rollers takes 12-20 minutes.

- According to the experience of the customer using our helical rolling line, the tool life with 3 shift work (24 hours +/- short breaks) of the tool kit is enough for 1 month of work.

- All adjustments from the operator's control panel or remotely.

- The production cycle is 10 - 12 sec. Installed power 140 kW.

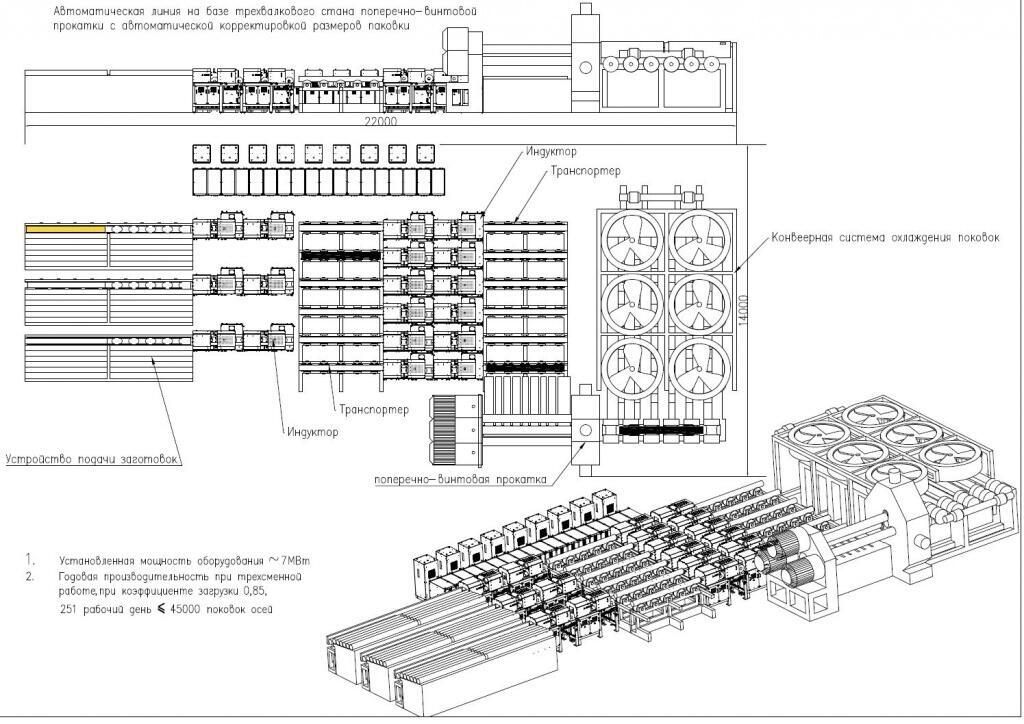

AMTengineering, together with ERSengineering, have developed and are promoting a section for the production of rough railroad axles on the basis of a three-roll mill of the HRL 6035 series of oblique (oblique) or cross-helical rolling.

The annual productivity of the site when working in three shifts 25 days a year with a load factor of 0.85 is from 50,000 to 200,000 pieces of forgings of a rough railroad axle (productivity depends on the speed and heating method). The productivity of the mill is 20-60 products per minute.