- Equipment

- Rollforming lines

- Lines for tile production

- Lines for corrugated profile production (mono)

- Lines for corrugated profile production (universal)

- Equipment for production of the elements of rainwater system

- Lines for roof elements production

- Lines for siding and special profile production

- The Equipment for manufacture of panels of prefabricated buildIngs

- Rollforming tool

- Flying scissors

- Slitting and cutting-to-length lines

- Cross-wedge rolling and Helical-rolling line

- Induction heaters

- Support equipment

- Main/

- Lines for corrugated profile production (universal)

Lines for corrugated profile production (universal)

Features:

The design of the universal lines for corrugated profile production allows to produce several types of different profiles at one piece of equipment. The change from one profile to another is done by changing the profiling tool.

Depending on the equipment class the tool change can be carried out by:

1. replacement of shaping rolls on the shafts;

2. change the amount of profiling stands;

3. use of quick removable modules.

Advantages: reduction of required space and communications, the ability to upgrade.

Disadvantages: there is no possibility to produce simultaneously all the profiles, the need for a thorough analysis of equipment utilization, the need for changeovers from one profile to another, the high reserve of solidity and power significantly increase the cost of this class of equipment.

| Material thickness, mm | 0,35 - 0,7 |

| Material width, mm | 1250 |

| Coating | zinc, polymer |

| Profile length, mm | 500 - 12 000 |

| Profiling speed, m/min | 40 |

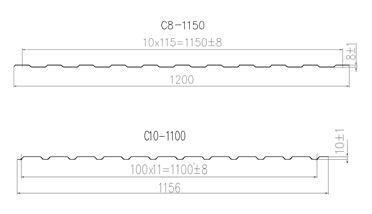

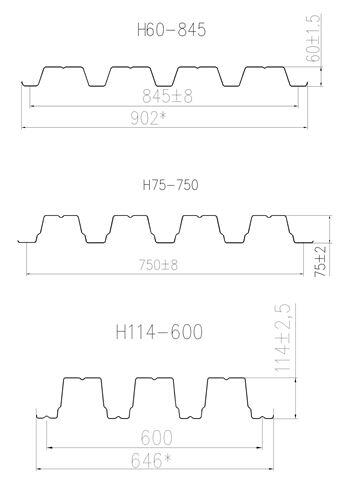

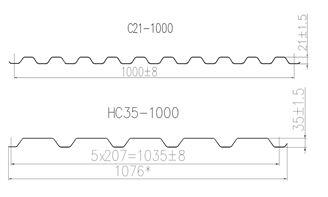

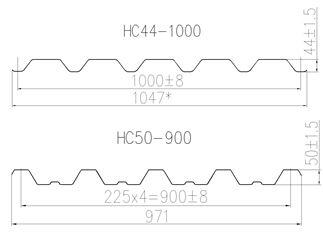

Samples of profiles:

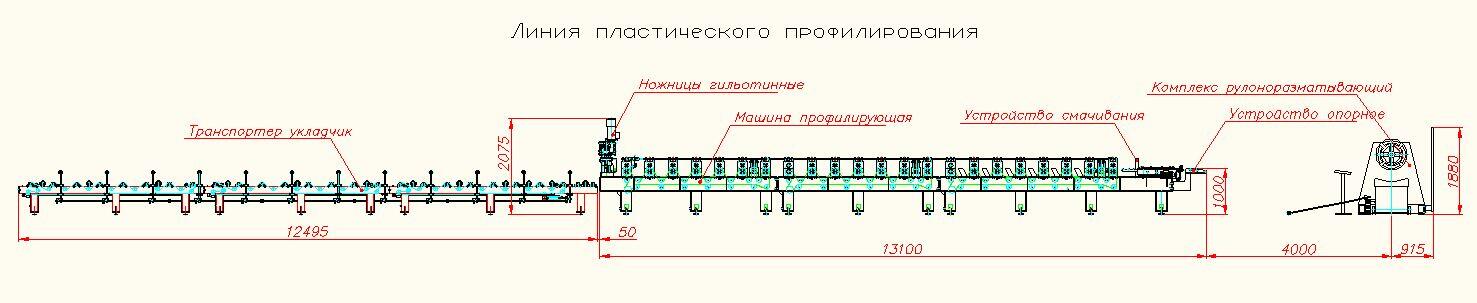

The line consists of:

- decoiler;

- loading trolley;

- lubricating system;

- rollforming mill;

- guillotine shears;

- conveyor stacker;

The equipment may optionaly include:

- receiving device;

- conveyor;

- flying scissors;

- packaging machine;

- additional devices for bending, perforation, engraving, etc.