- Flat cross-wedge rolling line new high quality cross-wedge rolling process for forgin and metalworking preform

- Business and mission

- Reference List

- Media Gallery

- Partners

- News

- Main/

- About company/

- Archive/

- News

Flat cross-wedge rolling line new high quality cross-wedge rolling process for forgin and metalworking preform

05.02.2024

Flat cross-wedge rolling line new high quality cross-wedge rolling process for forgin and metalworking preform

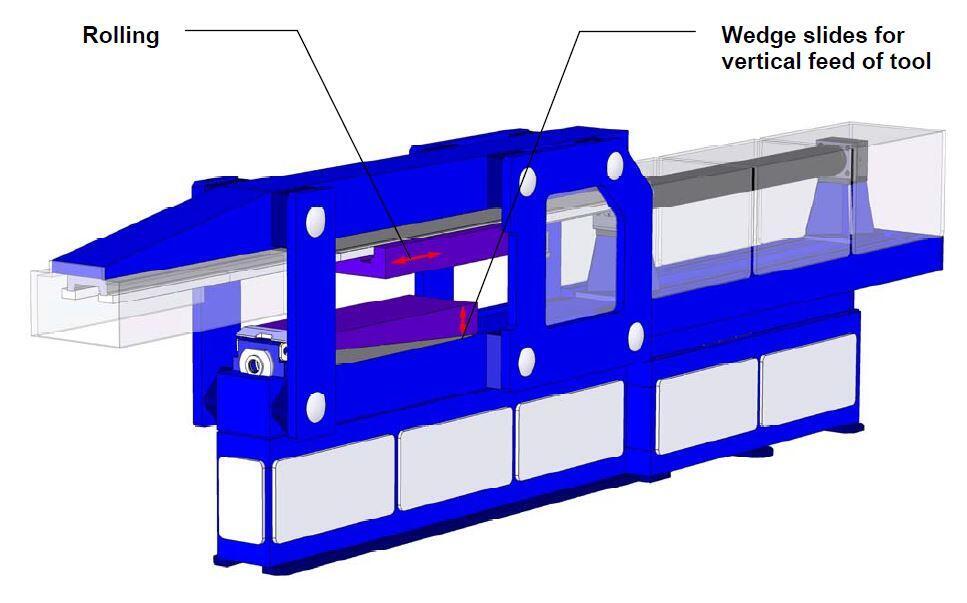

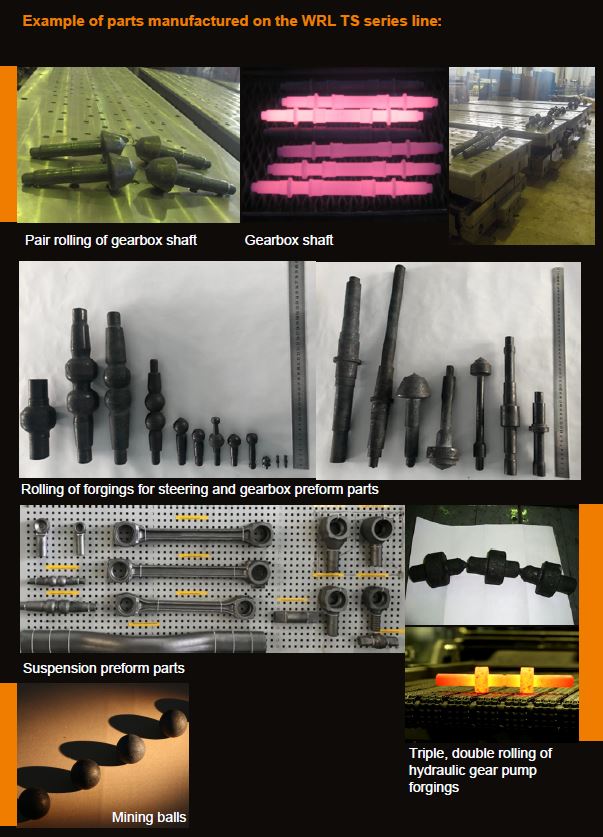

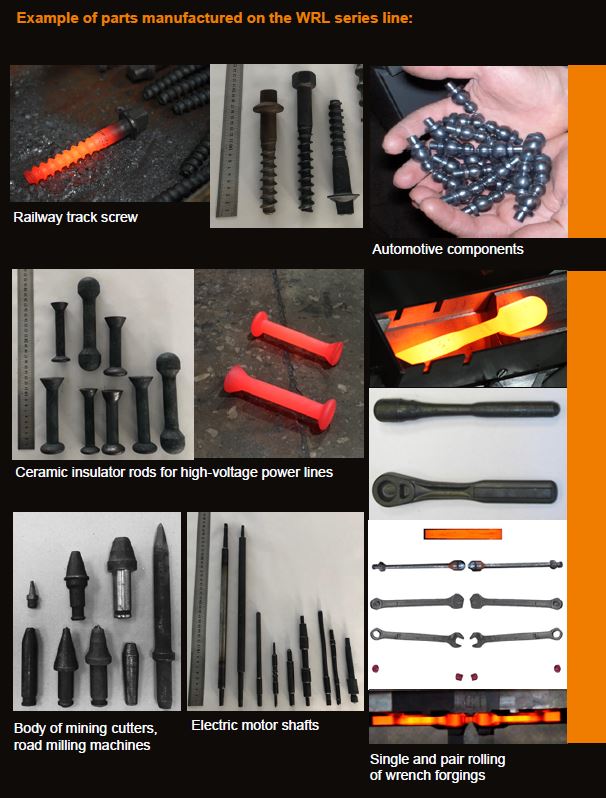

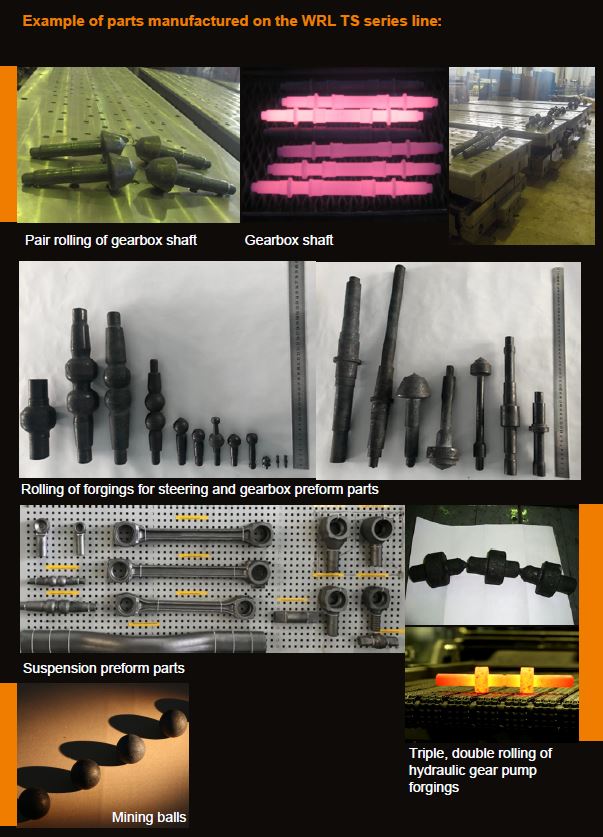

Cross-wedge rolling lines of the WRL, WRL TS series with flat tools are widely used for the production of forgings of the following products: gearbox shafts, main pairs of axles; cardan gear forks; electric motor shafts; blanks for low-burst stamping of automobile connecting rods, suspension arms, forgings of ball pins, metalwork tools; blanks for low-volume stamping of crankshafts, camshafts, balancer shafts; hydraulic pump gear forgings.

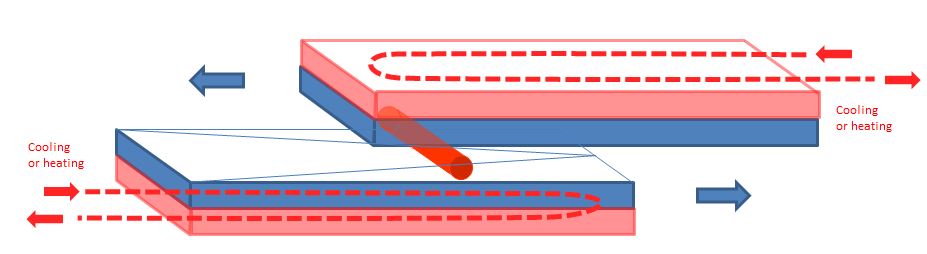

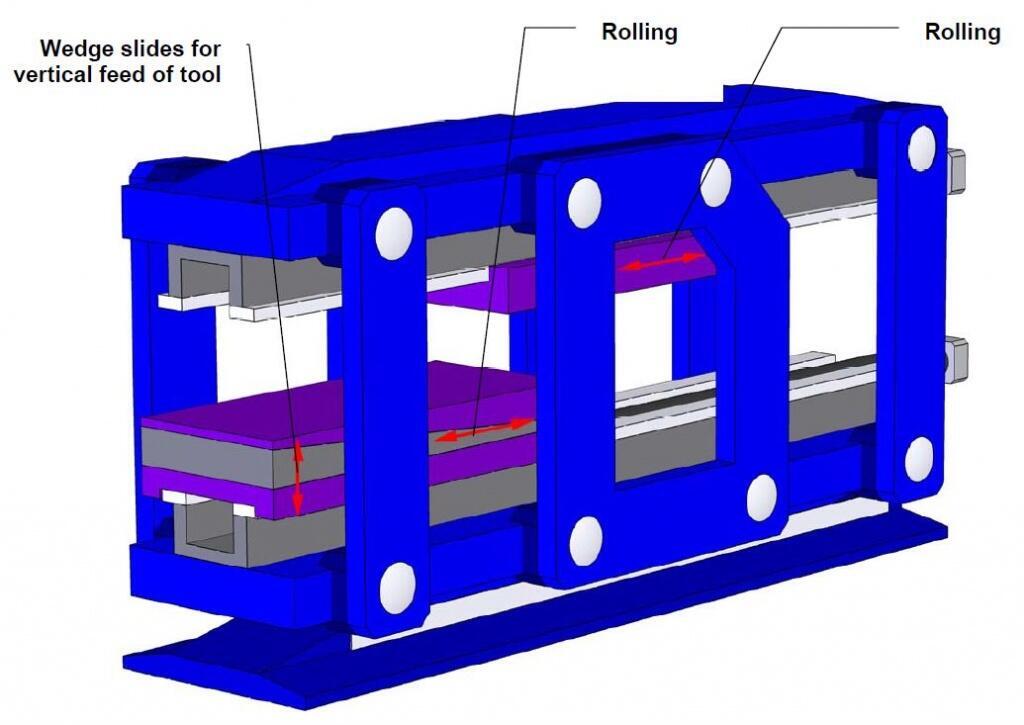

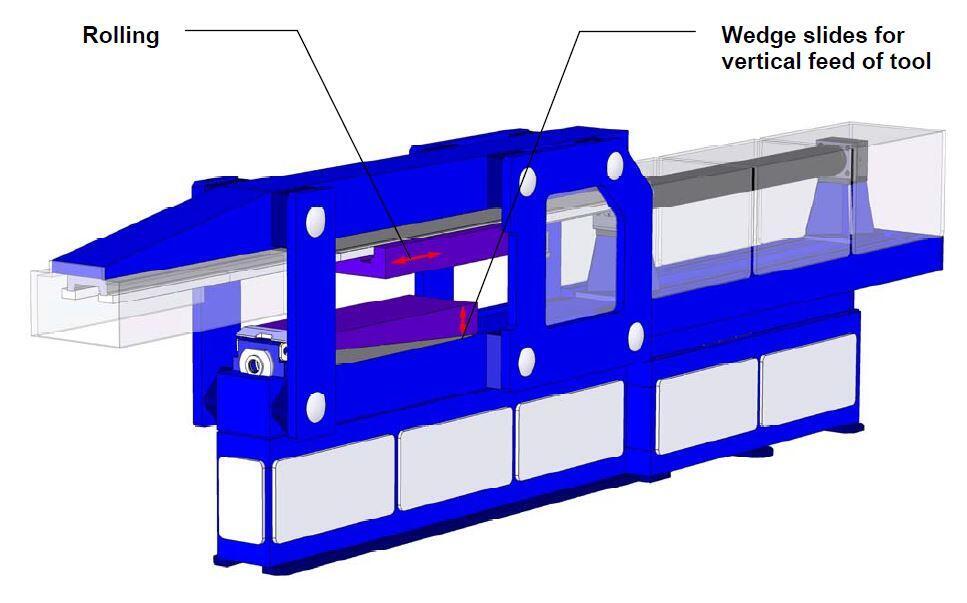

Flat tool cross-wedge rolling lines with one or two moving tools (WRL or WRL TS series):

The main advantages of using cross-wedge rolling technology:

- high productivity: from 200 to 1200 parts/hour (single, double, triple rolling of forgings);

- reduction in metal consumption (less workpieces, less waste; metal utilization coefficient up to 0.9)

- tolerance for rolled forging +-0.2 mm (no additional calibration required)

- reduction of machine time during finishing on CNC machines;

- strengthening of the part structure and lack of ellipticity;

- high precision of parts allows use in waste-free and flash-free stamping;

- increasing the service life of dies;

- on a flat tool, the Mannesmann effect is less pronounced (10-20% less) due to the more stable position of the contact areas of the part with the tool

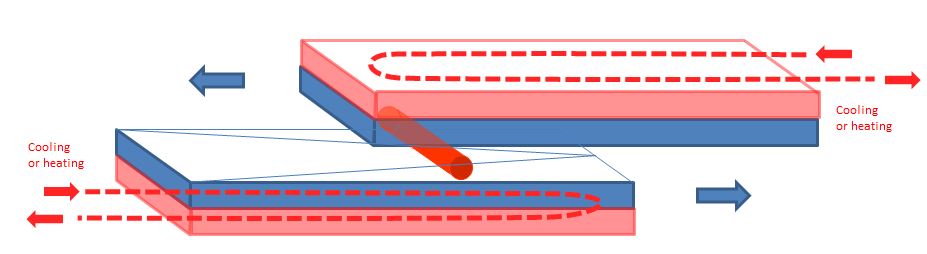

- working in conjunction with TFC induction heaters with continuous control of the input and output temperatures of the workpiece allows reducing energy costs and improving the quality of forgings by reducing scale formation;

- production and maintenance of tools does not require expensive equipment;

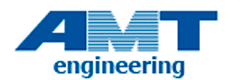

WRL lines use an efficient automatic cooling or heating system for rolling tools:

WRL and WRL TS Series:

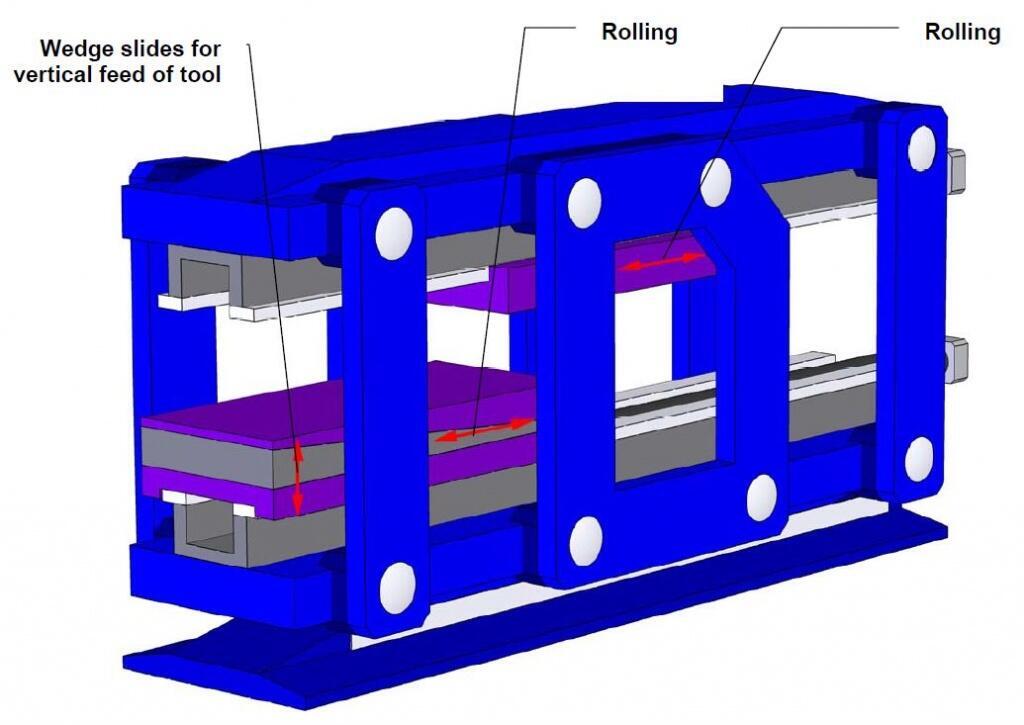

Innovative FLAT Wedge Rolling with Process Control

The WRL and WRL..TS Series lines from ERSengineering that are based on Cross

Wedge Rolling technology meet the constantly increasing market demands with

three key features:

· Simplification of tool settings, optimized machine guarding concept

· Further improvement of workpiece quality

· Increase in flexibility,analysis of the forming process with the aid of FEA simulation

WRL and WRL TS use advanced technical solutions

This results in special advantages to the customer:

· Fully automated Cross Wedge Rolling process

· High capacity, innovative tool design to increase tool life

· Mechanical or hydraulic power pack

· Vertical feed during rolling (dimensional correction via control system off-sets)

· Rolling speeds are individually programmable speeds

WRL series with one movable slide for production of parts Ǿ6-100mm parts

WRL TS series with two movable slides for production of parts Ǿ6-300mm parts

Competencies of the production complex

- High competencies and accumulated experience in the production of more than 1,200 types of forging blanks;

- Modern technologies and equipment, use of a computer-aided design system for hot cross-wedge rolling processes;

- Own design and production of equipment, technologies.

- Competitive price due to centralization of production, development of technology and tools.

- Organization of the production process from the preparation of blanks, production of forgings, if necessary, finishing machining allows organizing end-to-end quality control, eliminating defects in the batch, and increasing the profitability of production.

Production, supply, launch, tool design, technical support.

t. +375-17-500-31-13

amtengine@gmail.com

www.amtengine.com